| Vedaa CMS Pioneers in Equipment Reliability Services |

Phone: +91 9866065439 / +91 9849912069 |

| HOME ABOUT US PRODUCTS INNOVATIVE TECHNOLOGY CONTACT | |

Case Studies and Sample Reports |

|

CASE STUDY 1

Analytical Ferrography Provides Early Warning of Kiln Main Gear Box Failure

Cement Industry Overview

Cement manufacturing involves abrasion of the machinery which is brought about by particles from the raw materials. Therefore, it becomes necessary to have a wear detection technology to increase the service life of the machinery. These abrasive particles can create secondary wear and damage the equipment internals.

Ferrography helps to examine wear rate of the system internals irrespective of particle sizes along with material composition effectively and provides early warning of machine failures.

Plant: PENNA CEMENTS INDUSTRIES LIMITED

Location : Boyareddypalli, Andhra Pradesh

Lubricant : IOCL SMSP-320

Equipment : Kiln Main Gear Box

Sample Date: 14/07/11

Received Date:17/07/11

Test Date:07/08/11

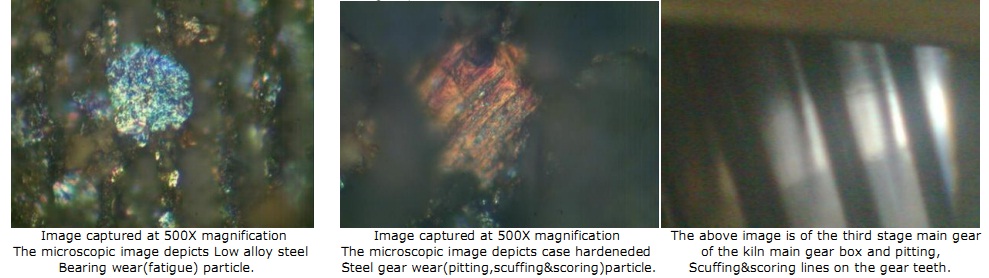

Observations in Ferrography: Case hardened steel gear wear (fatigue, scuffing & scoring)) particles of size ranging up to 90 microns are observed in abnormal quantities.

Low alloy steel bearing wear (fatigue) particles of size ranging up to 64 microns are observed in high concentrations. Sand/dirt particles are also observed in large quantities.

Recommendation: The report is rated marginal due to the presence of high concentration of gear wear and bearing wear particles. Change the lubricant as wear particle concentration is high. Note: Flush the system throughly before oil change. Resample after 20-25 days of equipment run to trend the generation of gear wear and bearing wear particles as the particles observed indicate fatigue and pitting in the gears and bearings. Close monitoring of internals is also advised.

Note : Vibration readings were normal.

Plant Officials Inspection: Plant officials taken initiative based on Veda’s recommendations gear box inspection was carried out on 09/08/11 and observations found that pitting, scuffing&scoring marks on the third stage main gear teeth.

The oil was drained from the unit and all the debris was thoroughly flushed from the gear box. The unit was then filled with new oil.

This timely identification prevented the unexpected breakdown of the entire unit, by requiring the replacement of only the single gear. Without this analysis, the unit would have continued operation until total failure.

Cost saving due to early detection including production cost is Approx.50 lakhs.

Case Study 2Raw Mill main Gear Box drained Oil purificationPlant: The India Cements Limited - Vishnupuram Location : Raw Mill Lubricant : Servo Mesh - 460 Component : Gear Box Oil Sample Date: 17/05/10 Received Date:20/05/10 Test Date:25/05/10 Raw mill main gear box oil of quantity 5000 ltrs was highly contaminated with water and particulate contamination. Mr.Vidyasagar who was working for plant as a Chief Manager-Mechanical asked me to test the oil for purification. We have tested physical & chemical parameters of oil along contamination test. Oil condition was O.K but contamination levels were high.

Contamination Levels Before Filtration:-

Sample Date{s) 17 May 2010 Size Range No. of Particles Class >4 microns 271348 25 >6 microns 29334 22 >14 microns 2096 18

ISO 4406:99 Results 25/22/18

The above results indicates that oil contamination levels are in unacceptable range.

After electrostatic filtration contamination levels were decreased to normal levels. Sample Date{s) 17 May 2010 Size Range No. of Particles Class >4 microns 3893 19 >6 microns 813 17 >14 microns 579 16

SO 4406:99 Results 19/17/16

Cost of Servomesh-460 per Ltr is approx.Rs.120/-,

Cost saving due to filtration is 5000 ltrs X Rs.120/- = Rs.6,00,000/- |

|

|

ABOUT US |

PRODUCTS |

INNOVATIVE TECHNOLOGY |

OUR

ASSOCIATES |

CONTACT Copyright © 2012 - 2022 Vedaa CMS. All Rights Reserved

|

|